Vibration Testing

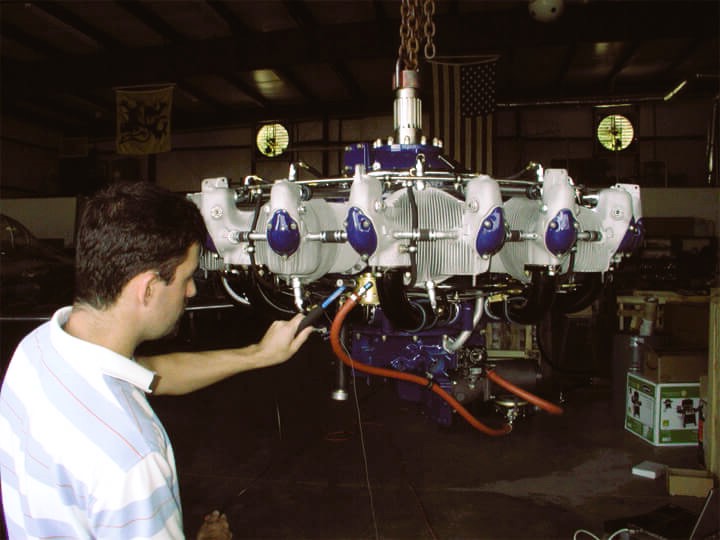

ServicesExploring the realm of vibrational scrutiny, WESTEST delves into the intricacies of subjecting a product, termed as the test sample, to an excitation of vibrational forces while closely monitoring its response. Our arsenal of vibration testing tools includes the multi-axial simulation table (MAST) system, vertical and horizontal vibration tables, and the electrodynamic shaker table.

These instruments serve as conduits for evaluating how the test sample reacts to vibrational inputs akin to those encountered during operational phases or transit. The primary objective is to affirm the product’s resilience against anticipated vibrational challenges throughout its entire service lifespan. Compliance with technical standards or the implementation of tailored client-specific procedures forms the crux of this evaluation. Notable vibration test standards for packaging and containers are outlined below.

WESTEST’s vibration test equipment boasts customization capabilities for various vibration tests, encompassing sinusoidal, random, and actual field simulation tests facilitated by RPC software. Our hydraulically controlled MAST system, vertical and horizontal vibration tables, cater to lower frequency applications (up to 100 Hz), while the electrodynamic shaker table addresses higher frequency vibration tests (up to 3,000 Hz).

Two prominent applications within our vibrational testing repertoire are sine sweep (resonance search) tests and vibration durability tests:

In sine sweep tests, the test sample, typically equipped with monitoring instrumentation, undergoes vibrational inputs at discrete frequencies. The data collected aids in identifying the natural frequencies of the test sample. This crucial information enables designers to mitigate resonance conditions that may lead to amplified responses and premature product failure. Early detection allows for design modifications to shift natural frequencies away from common service-induced vibrations.

Vibration durability testing, frequently conducted with sinusoidal, random, and field simulation inputs, involves subjecting the test sample to sustained vibrational inputs. This validates the long-term durability of a product when exposed to such vibrational stressors.

Conforming to Standards

WESTEST aligns with recognized standards for vibrational testing, including:

- CAN/CGSB-43.146: Design, Manufacture, and Use of Intermediate Bulk Containers for the Transportation of Dangerous Goods, Classes 3, 4, 5, 6.1, 8, and 9.

- ASTM D999 – 08(2015): Standard Test Methods for Vibration Testing of Shipping Containers.

- ASTM D4728 – 17: Standard Test Method for Random Vibration Testing of Shipping Containers.

- ASTM D7387 – 13: Standard Test Method for Vibration Testing of Intermediate Bulk Containers (IBCs) Used for Shipping Liquid Hazardous Materials (Dangerous Goods).

Did you like the article? Read also about Tilt & Rollover Stability Testing.

Should your required standards not be listed, our versatile vibration test equipment can be tailored to meet diverse testing needs. Feel free to reach out to us for detailed information.

Diverse Testing Arsenal

Our array of test equipment includes:

- Multi Axial Simulation Table (MAST)

- Hydraulic Horizontal Vibration Table

- Hydraulic Vertical Vibration Table

- Electrodynamic Shaker Table

- Somat eDAQ Data Acquisition System

If you would like to read more about this topic, you can visit Canada.ca.

Recent Posts

- The Role of Data Analytics in Optimizing Production Testing Processes

- Measuring Success: Key Performance Indicators for Production Testing

- The Interplay Between Production Testing and Continuous Improvement

- The Importance of Training and Skill Development in Production Testing Teams

- Strategies for Minimizing Downtime During Production Testing