Benefits of Implementing Automated Testing in Manufacturing Processes

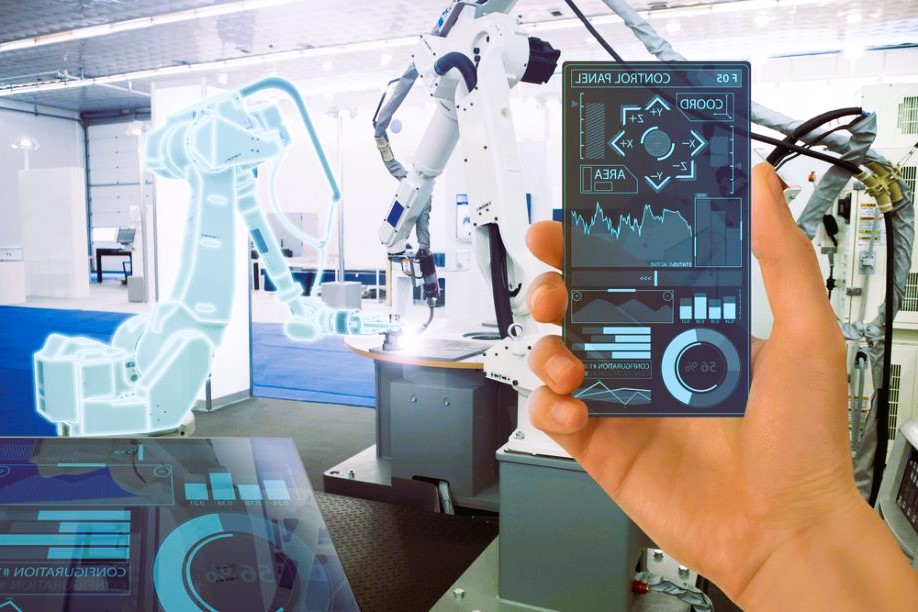

BlogIn the rapidly evolving landscape of manufacturing, the adoption of automation has become a key driver of efficiency, precision, and overall process improvement. One area where automation has proven particularly beneficial is in the realm of testing. Implementing automated testing in manufacturing processes offers a myriad of advantages, ranging from increased accuracy to enhanced productivity. In this article, we will delve into the various benefits that come with the integration of automated testing in manufacturing.

1. Precision and Consistency:

One of the primary benefits of automated testing is the unparalleled precision and consistency it brings to the manufacturing process. Automated testing systems execute predefined test protocols with a level of accuracy that surpasses human capabilities. This ensures that each product undergoes the same set of tests under identical conditions, minimizing variability and enhancing the overall consistency of testing results.

2. Increased Testing Speed:

Speed is a critical factor in modern manufacturing, and automated testing excels in this aspect. Automated testing systems can execute tests at a much faster rate compared to manual testing. This accelerated testing speed not only contributes to quicker throughput in production but also allows for timely identification of defects, reducing the likelihood of bottlenecks in the manufacturing process.

3. Enhanced Efficiency and Productivity:

Automation inherently enhances efficiency by streamlining processes and minimizing human intervention. In the context of testing, automated systems operate seamlessly within production lines, allowing for continuous testing without interruptions. This increased efficiency translates into higher productivity as testing cycles are optimized, and resources are utilized more effectively.

4. Scalability for High-Volume Production:

Manufacturers dealing with high production volumes benefit significantly from the scalability of automated testing. Automated systems can handle large quantities of products with minimal impact on testing times. This scalability is particularly advantageous in industries where mass production is the norm, as it ensures that testing processes can keep pace with the demands of high-volume manufacturing.

5. Reduction in Human Error:

Manual testing is susceptible to human error, which can lead to inaccuracies and inconsistencies in test results. Automated testing eliminates the risk of human error by executing tests precisely according to predefined parameters. This reduction in errors enhances the reliability of testing outcomes and contributes to the overall quality assurance of products. Do you like the article? Read also about Innovations in production testing technologies.

6. Comprehensive Test Coverage:

Automated testing systems can conduct a wide array of tests simultaneously, providing comprehensive test coverage. This ability to execute multiple tests in parallel ensures that all relevant aspects of a product are thoroughly examined. From functional tests to performance tests and beyond, automated testing contributes to a more holistic approach to quality assurance.

7. Real-time Data Analysis:

Automated testing systems generate vast amounts of data in real-time. This data can be analyzed instantaneously, providing valuable insights into the performance of products and the efficiency of manufacturing processes. Real-time data analysis enables quick decision-making, allowing manufacturers to address issues promptly and optimize production workflows.

8. Adaptability to Changing Requirements:

In the dynamic landscape of manufacturing, product specifications and testing requirements may change over time. Automated testing systems are inherently adaptable, making it easier for manufacturers to modify test protocols and accommodate changing specifications. This adaptability ensures that testing processes remain aligned with evolving industry standards and product requirements.

Linking to Standards:

The benefits of implementing automated testing in manufacturing processes are closely tied to industry standards. Standards provide guidelines and benchmarks for quality assurance, and automated testing plays a crucial role in achieving and maintaining compliance with these standards. For more information on standards in Canada, you can refer to authoritative sources such as Wikipedia.

Conclusion: Revolutionizing Quality Assurance in Manufacturing

The integration of automated testing into manufacturing processes represents a paradigm shift in quality assurance. From precision and speed to scalability and adaptability, the benefits are both diverse and impactful. As technology continues to advance, the capabilities of automated testing systems will likely expand, further solidifying their role as indispensable tools in the pursuit of excellence in manufacturing.

Manufacturers embracing automated testing not only enhance the quality of their products but also position themselves for increased competitiveness in the market. The efficiency gains, reduced testing times, and heightened accuracy contribute to a manufacturing environment that is not only technologically advanced but also more resilient and responsive to the demands of the modern industry.

Recent Posts

- The Role of Data Analytics in Optimizing Production Testing Processes

- Measuring Success: Key Performance Indicators for Production Testing

- The Interplay Between Production Testing and Continuous Improvement

- The Importance of Training and Skill Development in Production Testing Teams

- Strategies for Minimizing Downtime During Production Testing